Metal Scrap Hydraulic Pressure Compressor

Details

Description

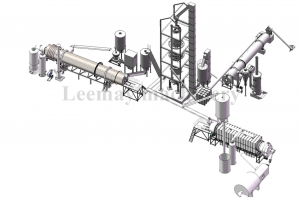

Metal Scrap Hydraulic Pressure Compressor is mainly used for cold pressing powders into high density briquettes, like mill scales, iron dust, copper chips, aluminum chips, silicon powder, slag powder and so on. The whole process does not need add any additives. The hydra u lic press briquette machine is widely used in steel plant, stockbreeding industry, foundry, copper and aluminum products production enterprises, etc.

Working principle

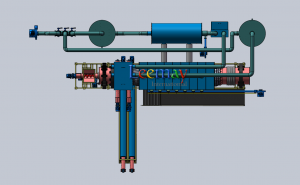

The Metal Scrap Hydraulic Pressure Compressor consists of upper and lower crossbeams, hydraulic cylinder assembly, material-feeding cylinder, mold, hopper, liquid filling assembly, etc.

The upper and lower crossbeams are connected by columns and nuts, and the front end of the main hydraulic cylinder is connected to the bottom of the upper beam by flange. The mold is fixed on the thick mold pad of the lower beam, and the mold sleeve is fixed in the mold. The punch is mounted on the underside of the center beam. Both die sleeves and punches are removable and replaceable.

There is an extractor cylinder located behind the lower die of the main unit. The extractor cylinder forms the bottom of the die cavity with the die sleeve when it is in the front position, and forms a space at the bottom when it is in the back position, which is convenient for the product to fall down and has the function of pushing the finished products out of the bottom of the die at the same time.

The liquid filling system is located on the side of the crossbeam to replenish the oil required for the fast moving of the main cylinder.

Features

(1) Adopt hydraulic transmission, PLC control, high compressing ratio, smooth operation.

(2) Use advanced cartridge valve and ensure continuous operation .

(3) Simple maintenance.

(4) Reasona b l e structure and 24-hour continuous working supported.

(5) Cr12MoV Alloy mold design, more durable lifespan.

Models & Specifications

| Contact : | Nana Cui |

|---|---|

| Phone : | +86-13592528737 |

| Email : | leemayco@gmail.com |

| Whatsapp : | +86-13592528737 |

| Address : | 1210 Rongcheng Building, No. 92, Jianshe Road, Zhongyuan District, Zhengzhou City, Henan Province, China. |