Coconut Shell Charcoal Carbonizing Furnace

Details

Description

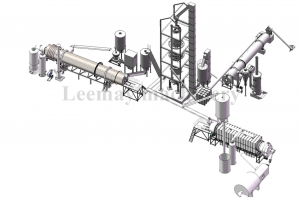

Coconut shell carbonizing furnace is used to process coconut tree trunks, roots, coconut shells, coconut leaves and other wastes produced in the process of coconut planting and processing, and the finished charcoal has high carbon content. Coconut shell carbonization equipment, in continuous carbonization process with automatic feeding and discharging, has the characteristics of short carbonization time, high carbonization output, good carbon quality, simple operability, good safety, good environmental protection.

Coconut shell charcoal,

made from coconut shell by carbonization equipment, is free-pollution, which is of great significance in new energy regeneration. When the carbonization process of coconut shell is completed, the active substances on the surface of coconut shell and other macromolecular carbon materials will be decomposed and adsorbed into the coconut shell carbon, which in turn generates carbon structures with various chemical properties. This makes the coconut shell carbon have good heat and radiation resistance, especially suitable for reprocessing to prepare coconut shell activated carbon. Coconut shell activated carbon is widely used for decolorization, deodorization, removal of organic matter and residual chlorine in central water purifiers, drinking water and industrial water.

Features

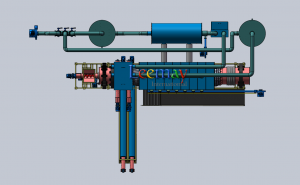

1. Coconut shell carbonization equipment is of drum structure, feeding coconut shell into the carbonization equipment can be carbonized 24 hours without smoke, uninterrupted operation.

2. The double drum design can dry the material quickly in the sealed environment and carbonize it with high temperature dry distillation, so as to ensure the quality of the finished charcoal.

3. The cooling discharging system in the coconut shell carbonization equipment can quickly cool down the carbonized material for easy storage.

4. Coconut shell carbonization equipment is equipped with smoke purification system, which can recycle the decomposed harmful gases for calcination and ensure that the carbonization environment is free of smoke and dust.

Working Principle

The coconut shells are carbonized and pyrolyzed in a high-temperature and oxygen-limited environment, the syngas generated during the whole production is recycled into fuel to supply heat for the carbonization furnace.

Models & Specifications

|

Model |

LMGL-Ⅰ |

LMGL-Ⅱ |

LMGL-Ⅲ |

|

Furnace Size/mm |

800×1200 |

1000×1600 |

1200×2000 |

|

Capacity/kg/h |

300-400 |

500-600 |

800-1000 |

|

Gas Burner/pc |

6 |

6 |

6 |

|

Main Stove/pc |

1 |

1 |

1 |

|

Subsidiary Stove/pc |

1 |

1 |

1 |

|

Fan Power/kw |

7.5 |

11 |

15 |

|

Small Fan Power/kw |

3 |

3 |

3 |

|

Transmission Motor/kw |

4 |

5.5 |

7.5 |

|

Feeder Power/kw |

4 |

4 |

4 |

|

Discharger Power/kw |

3 |

3 |

3 |

|

Furnace Inside Temp./℃ |

350-850 |

350-850 |

350-850 |

|

Flue Pipe Temp./℃ |

500-800 |

500-800 |

500-800 |

The coconut shell carbonizng furnace also can be specially designed and produced according to client's required capacity. Just feel free to contact us for the solution if you have new inquires.

| Contact : | Nana Cui |

|---|---|

| Phone : | +86-13592528737 |

| Email : | leemayco@gmail.com |

| Whatsapp : | +86-13592528737 |

| Address : | 1210 Rongcheng Building, No. 92, Jianshe Road, Zhongyuan District, Zhengzhou City, Henan Province, China. |