Sludge Carbonization Furnace

Details

Introduction

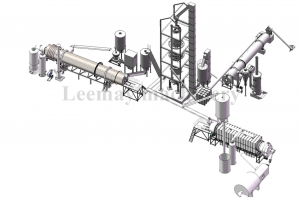

In the ever-evolving sustainable waste management, Leemay biochar Furnace takes the leadership with its high efficient Sludge Carbonization Furnace. This innovative technology redefines how we handle industrial sludge, turning it from a liability into a valuable resource. Let's delve into the furnace's features, advantages, and the exceptional benefits it brings to industries and the environment.The Sludge Carbonization Furnace is a cutting-edge solution designed to transform industrial sludge, a common waste product, into useful resources. This advanced furnace utilizes a controlled thermal process to convert sludge into biochar, a carbon-rich material with numerous applications across various industries.

Advantages of Carbonizing Sludge

Environmental Stewardship

By converting sludge into biochar, the furnace significantly reduces the environmental impact of sludge disposal. This sustainable approach prevents harmful emissions and contamination of soil and water.

Resource Recovery

The process extracts valuable carbon from sludge, creating a resource that can be used for energy generation, soil enrichment, and even as a raw material for manufacturing processes.

Landfill Reduction

Traditional sludge disposal methods often involve landfills, which take up valuable space and contribute to pollution risks. The carbonization furnace minimizes landfill dependency, promoting more efficient waste management.

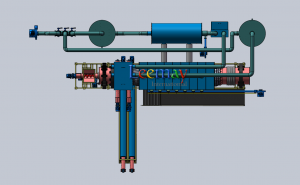

Furnace Features

Precision Control

Leemay Furnace's technology ensures precise temperature and oxygen control throughout the carbonization process, resulting in high-quality biochar production.

Safety Measures

The furnace is equipped with advanced safety features to ensure operator well-being and smooth operation.

Efficiency

Leemay's furnace design optimizes energy usage and process efficiency, minimizing operational costs while maximizing resource recovery.

Benefits of Sludge Carbonization Furnace

Economic Value

Convert waste into revenue by producing biochar, which can be sold or used internally for energy generation, reducing operational costs.

Environmental Leadership

Showcase your commitment to sustainability and environmental responsibility by adopting an innovative waste-to-resource technology.

Regulatory Compliance

Ensure compliance with stringent waste disposal regulations while contributing to a cleaner environment.

Empower Green Solutions

Leemay Furnace's Sludge Carbonization technology empowers industries to contribute to a greener future, where waste is no longer a burden but a valuable asset.

Revolutionize Waste Management

Join the waste management revolution with Leemay Furnace. Our cutting-edge technology transforms sludge into a resource, aligning profitability with sustainability.

Specifications of Sludge Carbonization Furnace

|

Model |

LMGL-Ⅰ |

LMGL-Ⅱ |

LMGL-Ⅲ |

|

Furnace Size/mm |

800×1200 |

1000×1600 |

1200×2000 |

|

Capacity/kg/h |

300-400 |

500-600 |

800-1000 |

|

Gas Burner/pc |

6 |

6 |

6 |

|

Main Stove/pc |

1 |

1 |

1 |

|

Subsidiary Stove/pc |

1 |

1 |

1 |

|

Fan Power/kw |

7.5 |

11 |

15 |

|

Small Fan Power/kw |

3 |

3 |

3 |

|

Transmission Motor/kw |

4 |

5.5 |

7.5 |

|

Feeder Power/kw |

4 |

4 |

4 |

|

Discharger Power/kw |

3 |

3 |

3 |

|

Furnace Inside Temp./℃ |

350-850 |

350-850 |

350-850 |

|

Flue Pipe Temp./℃ |

500-800 |

500-800 |

500-800 |

| Contact : | Nana Cui |

|---|---|

| Phone : | +86-13592528737 |

| Email : | leemayco@gmail.com |

| Whatsapp : | +86-13592528737 |

| Address : | 1210 Rongcheng Building, No. 92, Jianshe Road, Zhongyuan District, Zhengzhou City, Henan Province, China. |