Bamboo Carbonizing Plant

Details

Description

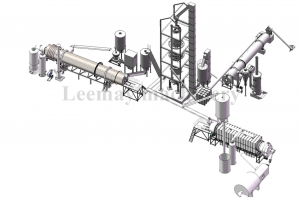

Bamboo, such as moso bamboo, reed bamboo, and shavings can be processed into bamboo charcoal by our carbonization charcoal furnace. Bamboo shavings can be directly carbonized into charcoal, and bamboo and bamboo trimmings and other larger pieces of materials need to be crushed to 2cm first by the crusher before going into the furnace. Bamboo charcoal produced by rotary charcoal furnaces is of good quality and high output. Bamboo charcoal powder can be used to process barbecue charcoal, hookah charcoal, activated carbon, and so on.Bamboo charcoal is obtained by heating and decomposing bamboo through carbonization equipment in a high-temperature and oxygen-shortage environment. We adopt the intelligent temperature control system to control the carbonization temperature easily, on the other hand, the main furnace of carbonization has good sealing performance, so the quality of bamboo charcoal is stable and keeps superior status.

The bamboo carbonization process goes through four stages, which are bamboo drying stage (temperature lower than 120℃), bamboo pre-carbonization stage (temperature 120℃-260℃), bamboo carbonization stage (temperature 260℃-400℃), and bamboo charcoal refining stage (temperature higher than 400℃).

The carbon monoxide, methane, and hydrogen produced in the process of bamboo charring are gasified and burned through the flue gas purification system and then the clean heat is returned to the combustion chamber, so as to achieve the efficacy of cyclic combustion.

Features

1. Adopt heat preservation technology to keep the temperature inside the furnace without emitting.2. Well-sealed furnace to improve the charcoal output capacity.

3. The excessive heat generated can be used for drying or burning the boiler.

4. The cooling discharger can shorten the charcoal cooling time.

5. The harmful smoke is well treated and the furnace running reaches the safe emission standard.

Process Flow Diagram

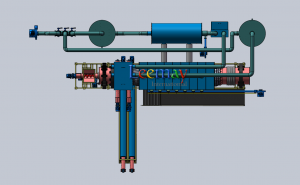

Structure of Carbonizing Plant

Models & Specifications

|

Model |

LMGL-Ⅰ |

LMGL-Ⅱ |

LMGL-Ⅲ |

|

Furnace Size/mm |

800×1200 |

1000×1600 |

1200×2000 |

|

Capacity/kg/h |

300-400 |

500-600 |

800-1000 |

|

Gas Burner/pc |

6 |

6 |

6 |

|

Main Stove/pc |

1 |

1 |

1 |

|

Subsidiary Stove/pc |

1 |

1 |

1 |

|

Fan Power/kw |

7.5 |

11 |

15 |

|

Small Fan Power/kw |

3 |

3 |

3 |

|

Transmission Motor/kw |

4 |

5.5 |

7.5 |

|

Feeder Power/kw |

4 |

4 |

4 |

|

Discharger Power/kw |

3 |

3 |

3 |

|

Furnace Inside Temp./℃ |

350-850 |

350-850 |

350-850 |

|

Flue Pipe Temp./℃ |

500-800 |

500-800 |

500-800 |

The coconut shell carbonizng furnace also can be specially designed and produced according to client's required capacity. Just feel free to contact us for the solution if you have new inquires.

| Contact : | Nana Cui |

|---|---|

| Phone : | +86-13592528737 |

| Email : | leemayco@gmail.com |

| Whatsapp : | +86-13592528737 |

| Address : | 1210 Rongcheng Building, No. 92, Jianshe Road, Zhongyuan District, Zhengzhou City, Henan Province, China. |