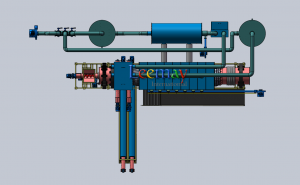

Rice Husk Carbonization Furnace

Details

Introduction of rice husk

Using carbonization plant, rice husks can be processed into biochar. Rice husk charcoal belongs to the category of biomass charcoal. It is produced through thermal decomposition and carbonization in a rice husk carbonization plant under high-temperature anaerobic conditions. It has the characteristics of lightweight volume and low thermal conductivity.

Application of rice husk charcoal

In Industry

In Water Source Treatment

Rice husk charcoal can effectively treat polluted water. Using the adsorption property of rice husk charcoal, the rice husk charcoal can absorb ammonia nitrogen elements from water, thereby reducing the degree of water eutrophication.

In Agriculture

After carbonizing, the rice husks have the effect of absorbing heat, so it can make the ground and water temperatures rise, which promotes plant growth and reduces cold damage. The loose and porous feature of rice husk charcoal has good air permeability, which increases the oxygen supply to the roots, enhances the water retention of sandy soil and reduces dry damage, and loosens clay soil and reduces wet damage.Rice husk charcoal has strong adsorption capabilities, absorbing mycotoxins and reducing nutrient loss. It can also eliminate odors in animal shelters, including those housing poultry. Furthermore, rice husk charcoal helps plant water absorption, resulting in thicker and healthier leaves.

Rice husk charcoal has fungicidal and ion-exchange effects, effectively preventing plant root rot. Spreading it on the soil surface around plants can effectively prevent insect pests.

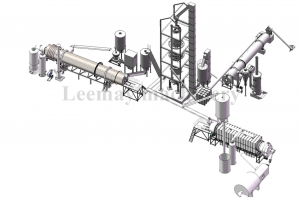

How to use rice husk carbonisation equipment to carbonise rice husks

The rice husk carbonization equipment uses agricultural waste rice husk as raw material and carbonize it into charcoal, which completely transforms the mixed flue gas produced in the carbonization process into pure combustible gas, greatly reduces the cost of heat energy required when the carbonization equipment runs, and improves the continuity and economy of the carbonization equipment.Features of Rice Husk Carbonization Furnace

1. The rice husk carbonisation equipment adopts intelligent control system, which saves labour and moves the development of intelligent automation.2. Rice husk carbonisation equipment solved the problem of how to implement the continuous working type and greatly increased the production capacity of the furnace.

3. Rice husk carbonisation furnace achieved the production process of carbon and gas co-production, low energy consumption, pollution-free green production mode.

Parameters of rice husk carbonisation equipment

|

Model |

LMGL-Ⅰ |

LMGL-Ⅱ |

LMGL-Ⅲ |

|

Furnace Size/mm |

800×1200 |

1000×1600 |

1200×2000 |

|

Capacity/kg/h |

300-400 |

500-600 |

800-1000 |

|

Gas Burner/pc |

6 |

6 |

6 |

|

Main Stove/pc |

1 |

1 |

1 |

|

Subsidiary Stove/pc |

1 |

1 |

1 |

|

Fan Power/kw |

7.5 |

11 |

15 |

|

Small Fan Power/kw |

3 |

3 |

3 |

|

Transmission Motor/kw |

4 |

5.5 |

7.5 |

|

Feeder Power/kw |

4 |

4 |

4 |

|

Discharger Power/kw |

3 |

3 |

3 |

|

Furnace Inside Temp./℃ |

350-850 |

350-850 |

350-850 |

|

Flue Pipe Temp./℃ |

500-800 |

500-800 |

500-800 |

| Contact : | Nana Cui |

|---|---|

| Phone : | +86-13592528737 |

| Email : | leemayco@gmail.com |

| Whatsapp : | +86-13592528737 |

| Address : | 1210 Rongcheng Building, No. 92, Jianshe Road, Zhongyuan District, Zhengzhou City, Henan Province, China. |